Pick-up

×

Easily handles all operating conditions

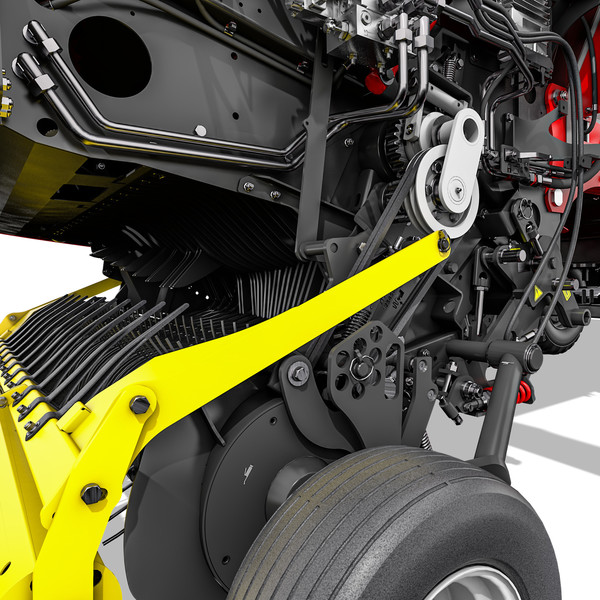

1 Cam track control

2 Centre support

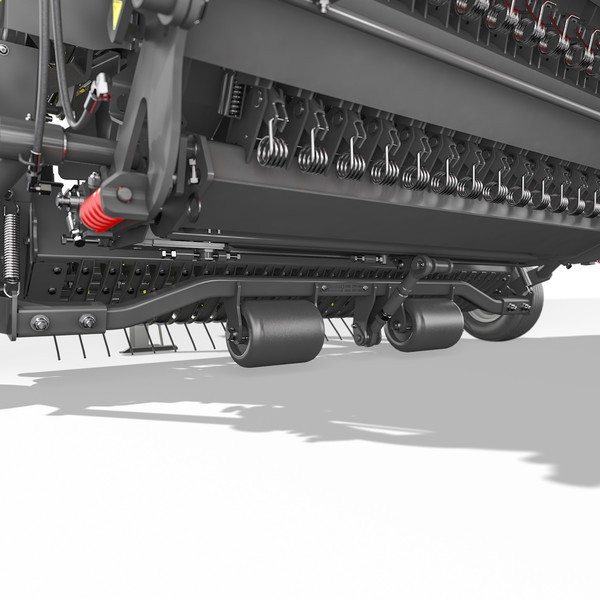

3 Swath roller

4 Adaptable jockey wheels

5 Trailing jockey wheel chassis

Controlled floating pick-up

The V-belt-driven controlled floating pick-up has an effective width of 1.800 mm according to DIN. It ensures clean and reliable crop pick-up in all operating conditions and when cornering.

V-belt drive

Low maintenance and durable

Cam track control

For perfect crop take-up and transfer

Crop swath roller

Optimum crop flow even at high driving speeds

Jockey wheels

Mounted rigidly or trailing for accurate height guidance

Jockey wheel chassis

Optional for the highest forage quality even in the most challenging terrain

Controlled pick-up

On the BOSS 3000 pick-up, the 5 tine carriers are controlled by a steel cam track. This design has the following advantages:

Slightly trailing tine angle for better contour tracking without scraping the ground

Active forage transfer to the loading unit by using the full length of the tine

Tine dips down at a right angle to prevent the forage from being drawn in

Less combing of the forage due to lower speed for better chopping quality (fewer lengthwise stalks)

Low speed causes less ejection - reliable crop collection driving downhill

Maximum conveying performance at high driving speeds

Reliable intake, even in difficult harvesting conditions

Able to adapt

The suspension of the pick-up allows side-to-side movement of 170 mm. In addition, the pick-up can also move down in the direction of travel, which ensures the crop is collected cleanly, even in deep troughs or over ridges. With a pick-up width of 1.800 mm, even high volume swaths are collected cleanly and tidily and cornering is made easier.

Crop take-up can be further optimised thanks to the automatic control of the parallel lift drawbar, which constantly keeps the pick-up's floating action within the optimum range. In addition, a trailing jockey wheel chassis is also available to prevent the pick-up from touching down in the centre.

Pick-up drive system

The pick-up is driven by two V-belts. These can adapt perfectly to the movements of the pick-up. At the same time, they serve as overload protection. Maintenance and wear are minimised.

The pick-up disengages and switches off automatically when it is lifted at the headland or in the clamp. This makes it easy to drive over swaths and through the clamp.

Swath roller

The swath roller with crop transfer rods deliver optimum crop flow even at high travelling speeds. This is standard on the BOSS 3000 and can be adjusted to match different sizes of swath.

The angle of the roller and the crop transfer rods can be adjusted.

Jockey wheels

Rigid jockey wheels are fitted as standard. These are recommended for working on slopes and for fields with few curves.

Steered jockey wheels are available as an option for optimum conservation of the sward, even when cornering. The height of both jockey wheel versions can be easily adjusted using a pin-in-hole matrix.

A changeover system on the jockey wheels allows an additional selection between optimum ground tracking at the point of tine engagement, and optimised clearance to make it easier to drive over the clamp, or through awkward field entrances.

Jockey wheel chassis

An optional jockey wheel chassis behind the pick-up ensures reliable guidance on bumpy terrain and prevents the side jockey wheels from sinking into wheel marks.

This stops the tines from scraping the ground even in the toughest conditions and minimises dirt ingress.

The synthetic rollers are rounded on the sides to prevent dirt from sticking and protect the sward when cornering.