Best working results

×Best working results

Rotor drive

Best working results for seedbed preparation

Reducing costs in arable farming has the highest priority. Today's farmers need the right technology to provide the best conditions for germination and growth as well as rapid and uniform emergence.

A power harrow working together with a seed drill is a high output and cost effective combination for perfect sowing results.

The heart of the machine - the rotor gearbox unit

An extended service life is only possible thanks to precision machining and strong connections. At PÖTTINGER this level of high quality goes without saying.

Thick-walled gear sump made of fine-grained steel – smooth running and extremely resistant to twisting.

Large gears directly above the bearings for a secure seat on the rotor shaft

Bearing housing welded to the central brace and bottom of trough. An exact spacing between each rotor is guaranteed as a result.

Direct transmission of power from the gearbox to the bevel gears

Tapered roller bearings with robust, single-piece bearing housing

Integrated tine holders

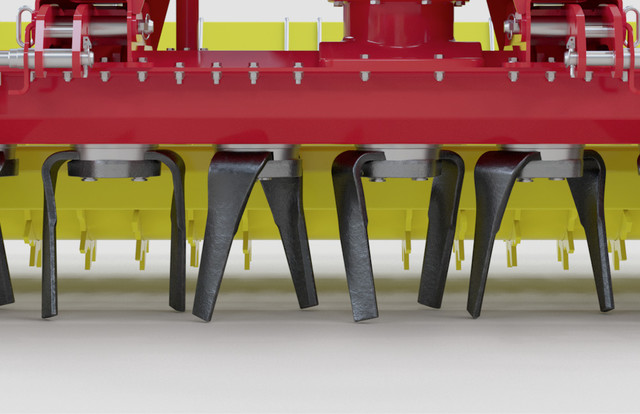

Integrated tine holders

The tines on the LION power harrow guarantee effective cultivation for intensive loosening and uniform tilth.

15 or 18 mm thick tempered tines attached centrally by just two bolts; this allows for ease of maintenance

Bolts and lynch pin are protected from soil and from working loose

The lower bearings are located as close as possible to the tine carrier.

The upper and lower bearings are spaced as far apart as possible to reduce load and minimise stress

Stones cannot become trapped

Harvest residues do not wrap around the tines

Perfect interaction between tines and levelling board

The rear levelling board is standard and is set automatically with the depth of the rear roller; no readjustment is necessary.

Reliability

LION power harrows guarantee extremely smooth running and high strength. These machines operate reliably even in the hardest endurance conditions and heaviest soils.

The tines on the LION power harrow are mounted securely on the tine rotor with a large surface area of contact.

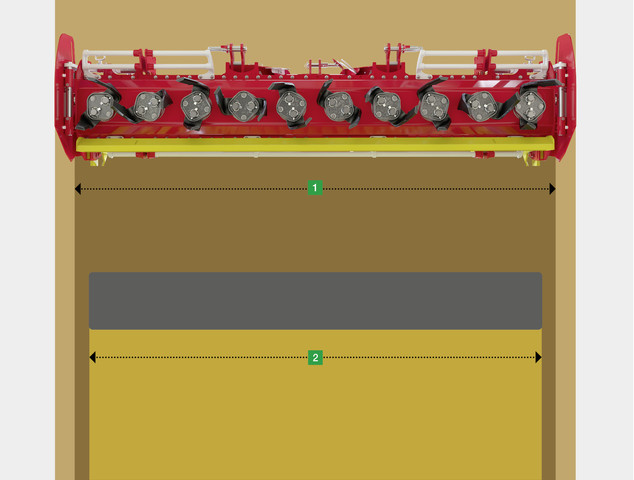

Effectiveness over the entire working width

LION - Effectiveness over the entire working width

1. LION 3.0 metre wide power harrows - effective working width 2.99 m

2. Comparable 3.0 metre wide power harrows - effective working width 2.90 m

The specified working width is precisely maintained and cultivated with LION power harrows:

LION 3.0 m -> 2.99 m

LION 4.0 m -> 3.99 m

All the drill coulters are on cultivated soil - even along the outermost edge.

Maximum strength

Large dimension gears

The high strength gear trough provides the gearbox with excellent stability.

Durability thanks to:

Large dimension gears

60 mm diameter rotor shafts

Robust tapered roller bearings and wide bearing spacing

Precision in every detail

The bearing housings are welded into the box section with the central brace before being machined on the CNC machining centre.

This sequence ensures exact axle spacing between each rotor: This is the guarantee for extremely smooth running and a long service life.

DURASTAR tines: coated and proven in the field

Up to 60 % longer service life thanks to special coating

15-mm and 18-mm-thick reversible tines

Excellent retention of shape

Consistent work quality