Maximum flexibility

×Maximum flexibility

VITASEM and LION in action

Flexibility for all conditions

PÖTTINGER offers you tailor-made systems for every type of soil and every size of operation. Setting up for different soil conditions must be quick and straightforward. The LION power harrow is the right choice for you.

Flexibility with a choice of mounting configurations

Easy mounting on different tractors (Cat 2/Cat 3); extendible lower linkage mountings for different tyre diameters

VITASEM and AEROSEM seed drills from Pöttinger can easily be fitted

HYDROLIFT

Hydraulic mounting system for seed drills with height and length adjustable retention hook

Two hydraulic cylinders guarantee a maximum lifting power of up to 2.4 t for heavy mounted seed drills

Lifting height limiter optional

Hydraulic or mechanical - it's your choice

Choose between mechanical and hydraulic top link depending on the model of seed drill.

Implement mounted with mechanical top link.

The centre of gravity is in front of the rear roller, extremely close to the tractor.

The additional weight of the seed drill on the roller provides even better consolidation of the seedbed

The gap between the coulter rail and the rear roller is minimised to form a compact unit.

The roller and seed drill form a single unit, the implement mounted drill is fixed to the rear roller on mounting pins and guided in parallel by the top link.

Consistent drilling depth even when changing the working depth of the power harrow using the rear roller

Implement mounted with hydraulic top link

The optional hydraulic top link on VITASEM models tilts the seed drill closer to the power harrow, making the combination even more compact.

The centre of gravity is positioned close to to tractor, this is especially necessary with a full seed hopper

High ground clearance of drill coulters at headlands

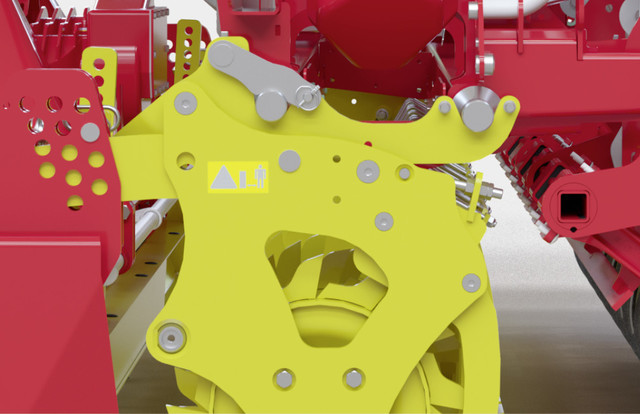

The LION as an all-rounder

Compact combination

1. Compact combination - close to tractor

2. The weight of the seed drill is carried by the rear roller

The LION power harrow is not only impressive when operated solo but also shows its strengths in combination with all PÖTTINGER implement mounted seed drills. You can use the LION power harrow together with VITASEM, AEROSEM or TEGOSEM. Mounting and removing the drill using the rear roller is quick and easy, without the need for tools.

Mounting of the seed drills on the rear roller is unique and has further advantages:

The additional weight of the seed drill is carried entirely by the rear roller.

The centre of gravity of the combination unit is located close to the tractor.

The power harrow can move up and down independently of the seed drill.

The drilling depth is not influenced by changing the working depth on the power harrow.

The best centre of gravity

The weight of the machine alone is only decisive at first glance. When the seed hopper is full, the centre of gravity situation can change quickly. That is why PÖTTINGER focussed on compact design during development. The influence of the seed hopper is relatively small in comparison. This results in a less weight off the front axle even when the seed hopper is full.

On AEROSEM seed drills the centre of gravity lies between the power harrow beam and the rear roller.

On VITASEM models, the centre of gravity acts on the front section of the rear roller.

The optional hydraulic top link tilts the VITASEM implement mounted seed drill forwards at the headland. This shifts the centre of gravity even closer to the tractor.

Centre of gravity with seed hopper empty

Centre of gravity with seed hopper full

1. PÖTTINGER with seed hopper empty

2. Comparable combinations with seed hopper empty

3. PÖTTINGER with seed hopper full

4. Comparable combinations with seed hopper full

Focus on weight

The aim of the development was to manufacture all parts that project (far) to the rear, in particular coulters and loading platform, using special materials. PÖTTINGER uses aluminium components like the ones used in the automotive industry. These are technically advanced and have the same capability as steel.

For further weight optimisation, levelling tines can be dispensed with, depending on the type of coulter.