To make work easier for you

×To make work easier for you

_ausschnitt.jpg)

Setting the working depth

Clever details

Quick and uncomplicated adjustment to different operating conditions is an important factor these days. PÖTTINGER power harrows provide some clever details that simplify your working day.

Setting the working depth

The working depth of the power harrow can be flexibly adjusted by simply repositioning the bolts in the hole matrix.

Automatic levelling board adjustment

The rear levelling board is standard and is set automatically with the depth of the rear roller.

Over the full working width the levelling board is always at a consistent distance from the tines

Perfect seedbed without re-adjustment

The system is preset using a hole matrix bar on the side, which is easily accessible and reliable even after many years of use

Optional:

A front levelling board in the same design as rear board

Bout markers on the power harrow (except CLASSIC models)

Side boards

_ausschnitt.jpg)

Side boards

Depending on the model, LION power harrows are equipped with the right side boards to deliver tidy work within the specified working width while maintaining the necessary transport width.

LION 253 CLASSIC, LION 303 CLASSIC, LION 303.12 CLASSIC:

Side boards can be folded upwards with easy depth adjustment using slotted holes

Can be fixed in working position

Can be folded up for transport

Transport width less than 2.5 m or 3.0 m

LION 303, LION 303.12, LION 403, LION 3002, LION 4002:

Infinitely height-adjustable using slotted holes

Simply fold upwards for transport

Optional: parallel linkage

Optional: Unique side board mounting, the spring remains pre-tensioned on the machine when raised so the side board can be easily folded up.

PTO shaft holder for easy accessibility

_ausschnitt.jpg)

PTO shaft holder

The PTO shaft can be placed on a convenient fold-away support. When hitching up the LION power harrow to the tractor the PTO shaft is already positioned close to the PTO shaft stub, making it easy to couple up.

Features with convincing arguments

Constantly changing operating conditions make a large number of adjustment options necessary. With LION power harrows from PÖTTINGER, these adjustments can be carried out easily without the need for tools.

Perfect mounting - low PTO shaft angle in operation

_ausschnitt-02.jpg)

Perfect linkage

For a long service life and smooth running of the PTO shaft, it is important that the power harrow can be attached perfectly to a wide variety of tractor geometries.

The length and width of the lower linkage mountings can be adjusted without the need for tools

Optimum length and angle of the PTO shaft

Ideal for machinery rings with different tractor brands

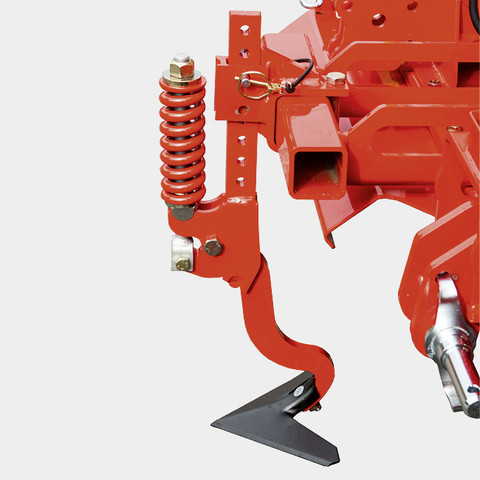

Track eradicators

Track eradicators

Spring-mounted track eradicators are optional on all LION power harrows. At PÖTTINGER these are spring-mounted to protect against stones and foreign objects.

The working depth can easily be adjusted without the need for tools.

Up to 2 tines per coulter are possible

Spring-protected side boards

_ausschnitt.jpg)

Spring-protected side boards

The side board mounted on springs helps to create a clean and even seedbed in heavy and stony soils. The special feature here is that the spring remains pre-tensioned on the machine when the plates are folded upwards into the transport position.

Optional for all LION power harrows (except the CLASSIC series)

Track markers

Bout markers

With PÖTTINGER the bout markers can be mounted either on the seed drill or the power harrow.

Hydraulic bout markers for reliable activation also on slopes

Hydraulic operation

Transport interlock

Setting the intensity of the marking

Shear bolt as overload protection

Optional for all LION power harrows (except the CLASSIC series)

Making work easier with technology at the highest level

Constantly changing soil conditions require changes to the tine positions. Practical experience has shown that only what can be done easily is then really done.

LION power harrows combine technology and convenience in one to deliver the best working results.

It's so easy - Quick-fix tine changes

The Quick-fix tine system provides a quick and safe solution for even more working convenience.

You can change the tines in just a few simple steps - it has never been so easy.

Quick-fix tines

1. Remove lynch pin and lock pin

2. Remove tines

3. Fit new tines

4. Clamp in place - finished

Universal tines for every operation

Universal tines

LION power harrows with 10 tines can be used both as rotary harrows and rotary cultivators. All that is needed is for the tines to be repositioned.

One shape of tine covers standard drilling, mulch drilling and direct mulch drilling.

This ensures optimum mixing and good quality tilth at seed slot level right across the entire working width.

Sweeping tine position - rotary harrow

In this position, the tines produce a fine tilth at seed slot level.

Sweeping tine position

Finer particles of soil are concentrated at the level of the seed

Larger clumps and harvest residues remain on the surface

Protection against erosion

Standard for every tine thickness

Aggressive tine position - rotary cultivator

In this position, the tines aggressively break up the soil and optimum mixing is guaranteed.

Aggressive tine position

The soil is broken up from below

Harvest residues are incorporated effectively

Only possible with 18 mm thick tines