More reliability in the field

×More reliability in the field

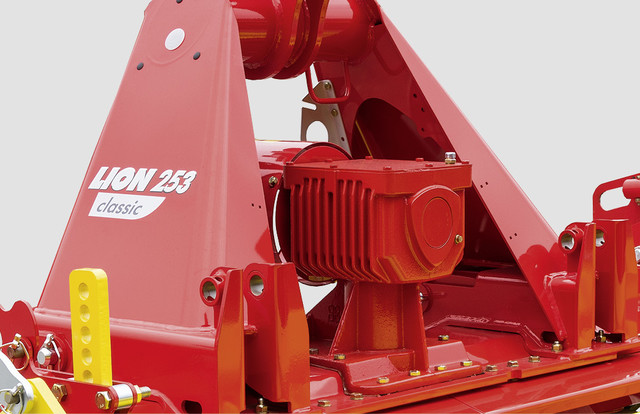

LION power harrows

Kit you can rely on

LION power harrows guarantee extremely smooth operation and high strength. These machines operate reliably even in the hardest endurance conditions and heaviest soils.

Proven technology

The tapered roller bearings in PÖTTINGER power harrows have been proving their strength and reliability for more than 25 years. Nowadays this technology is widely used in every type of vehicle: trucks, cars and in the construction industry.

Rugged headstock

LION power harrows deliver the best working results with a rugged headstock and a high level of flexibility.

Clevis type mounting lugs adjustable in width and category: CAT 2/2, CAT 3/3, CAT 3/N

Bumpy ground between the tractor and power harrow is compensated for by the floating function of the lower linkage arms

Depending on the tractor model, the mounting lugs can telescope out three fold to bring the power harrow as close as possible

Additional side struts on LION 403 and 4002 models

Smooth, quiet operation in the field

Regardless of whether it is fitted with a changeable speed gearbox, CLASSIC gearbox or manual gearbox; all LION power harrow models are smooth running during operation and at headlands.

LION CLASSIC gearbox

LION CLASSIC gearbox

Straightforward fixed-speed gearbox up to 140 hp

Gearbox input stub mounted far back

Longer PTO shaft for a larger angle and smoother operation

No rear PTO shaft

LION changeable speed gearbox

_ausschnitt.jpg)

LION changeable speed gearbox

Flexible choice of rotor speed by changing the gears

PTO shaft at only a minimal angle with incoming gear placed well back

Protected by a cam-type clutch

The gearboxes are equipped with cooling fins.

Optional: rear PTO shaft

LION manual gearbox

For the folding LION models up to 270 hp

Impressive technology

An extended service life is only possible thanks to precision machining and strong connections. At PÖTTINGER this level of high quality goes without saying.

Robust - smooth-running - durable

The LION power harrows provide the highest strength, smooth-running and long service life, an excellent combination for more reliability in the field.

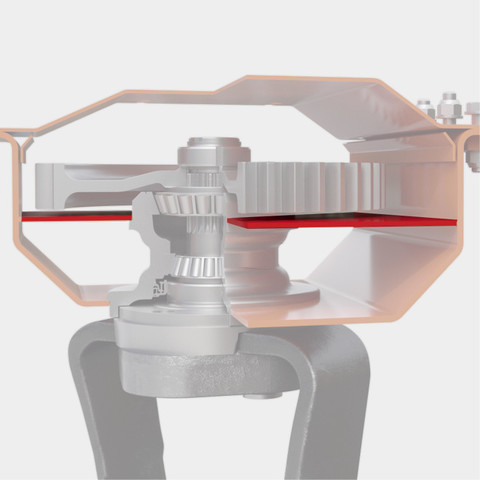

Rotor unit

1. Gear trough supported in the centre

2. Tapered roller bearings with robust, single-piece bearing housing

3. Wide spacing between the upper and lower bearings

Gear trough supported in the centre

Gear trough

The deep gear trough is formed from a single piece. The welded central brace provides additional stability. Above the central brace the gears and bearings run submerged in semi-liquid grease.

Tapered roller bearings with robust, single-piece bearing housing

Tapered roller bearings

The bearing housings are welded into the box section with the central brace before being milled on the CNC machining centre. This ensures exact rotor-to-rotor spacing and guarantees smooth-running and a long service life.

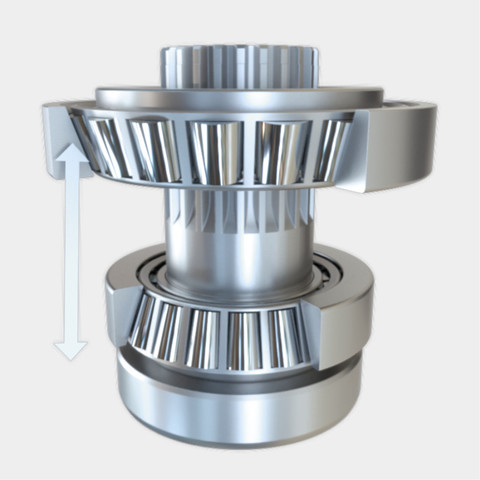

A bearing for eternity

Tapered roller bearing spacing

A wide support distance between the upper and lower tapered roller bearings reduces the load. The lower bearing is located close to the tine carrier. This takes the stress off the bearing and reduces wear. The labyrinth seal carefully seals inwards and outwards, no ingress of dirt.

Dimensions of tine rotor shaft:

50 mm on LION up to 200 hp

60 mm on LION above 200 hp